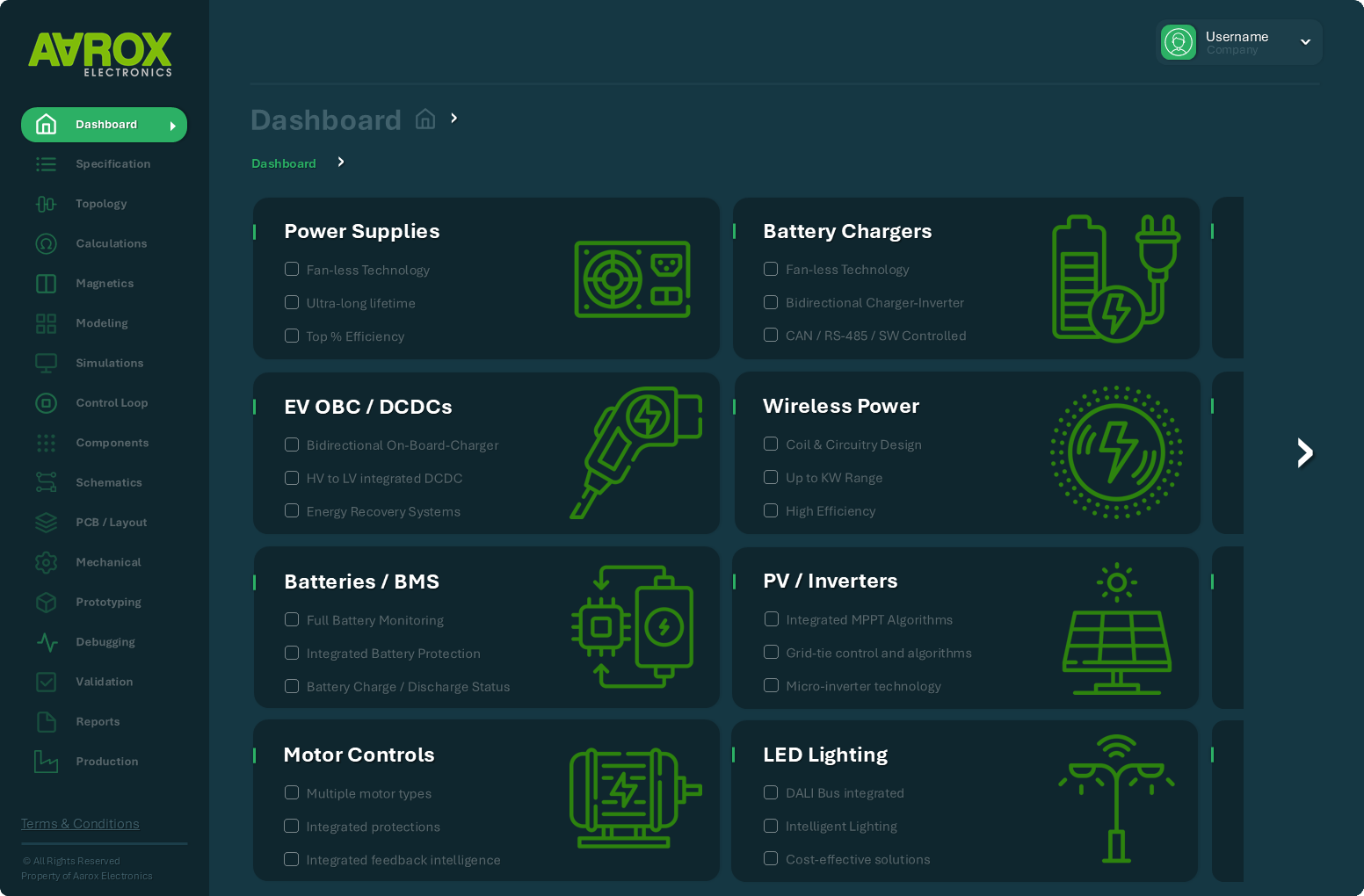

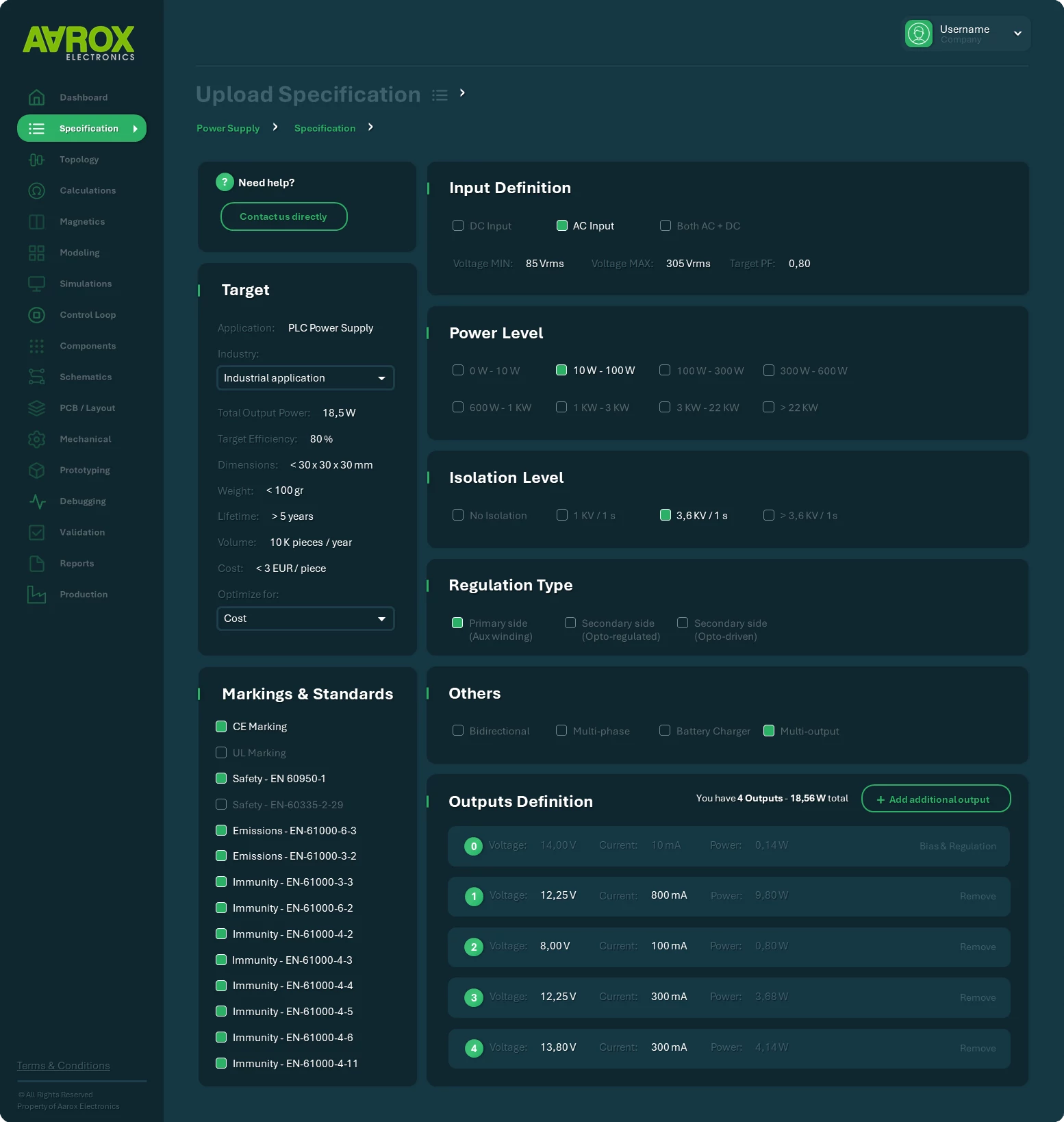

Starting from a specification

or even from a blank sheet

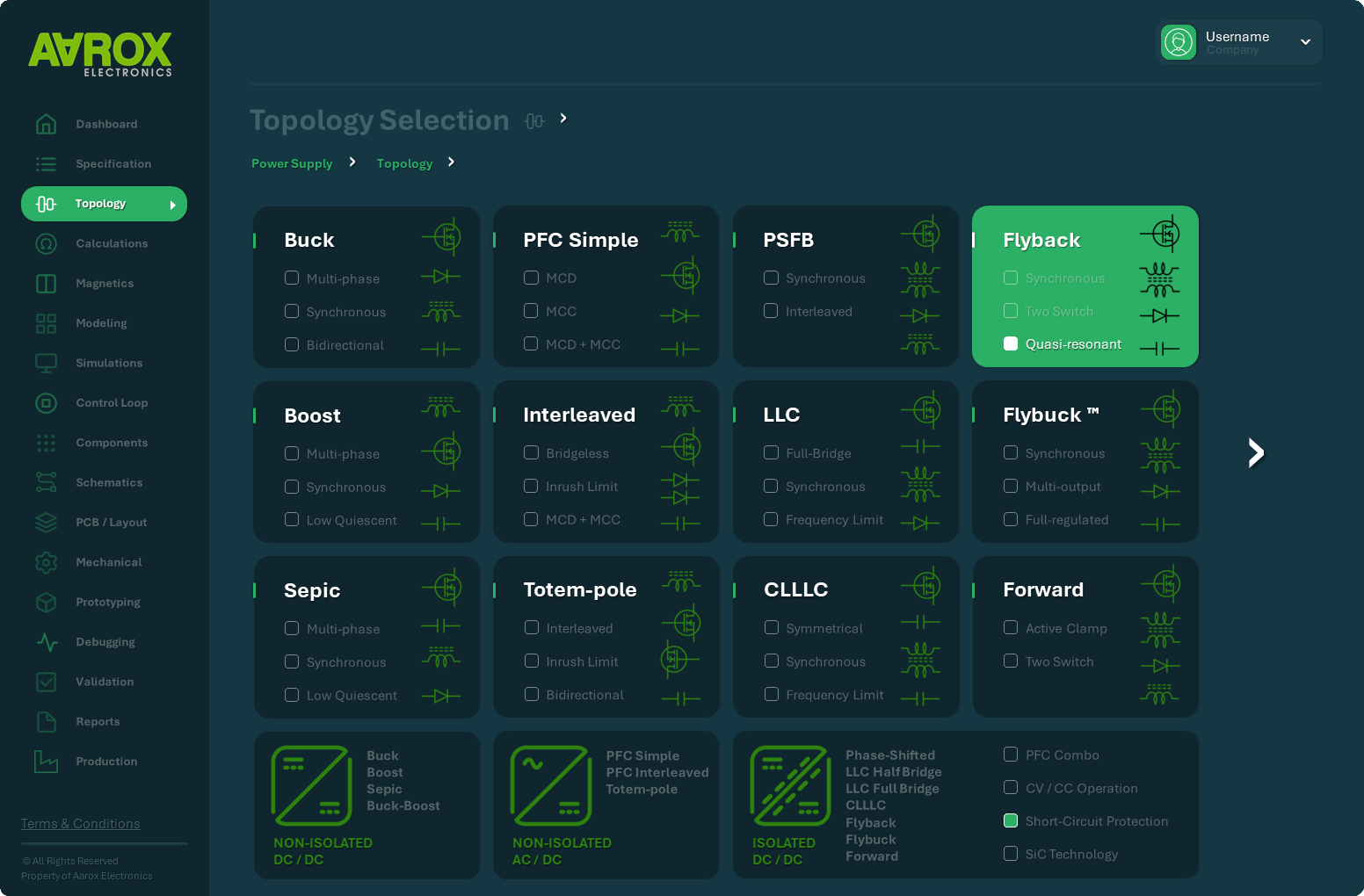

From small converters

To complex ZVS topologiesWith many projects

Validated and testedTaking into account

Cost and EMC from day oneIncluding embedded SW

From drive up to control

- 1. Topology Calculations

We have a proprietary SW to fully calculate and analyse many topologies and power systems. With this, we can easily compare and optimize a design from a very early stage, giving extremely accurate results, including COST.

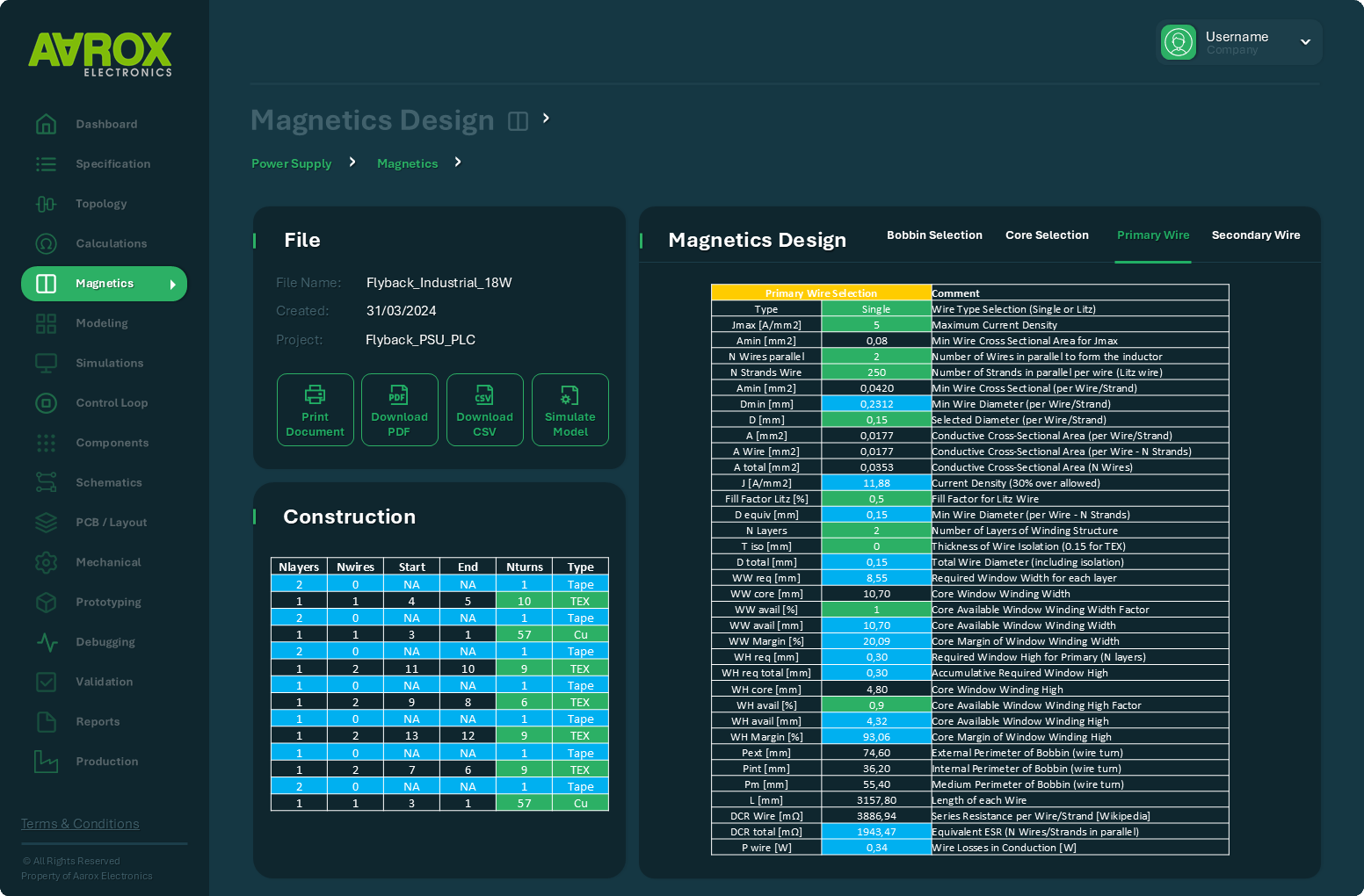

- 2. Magnetics Design

We understand the complexity behind these components, so we get involved to the minimum detail in designing, optimizing, testing and manufacturing the CORE of a power system.

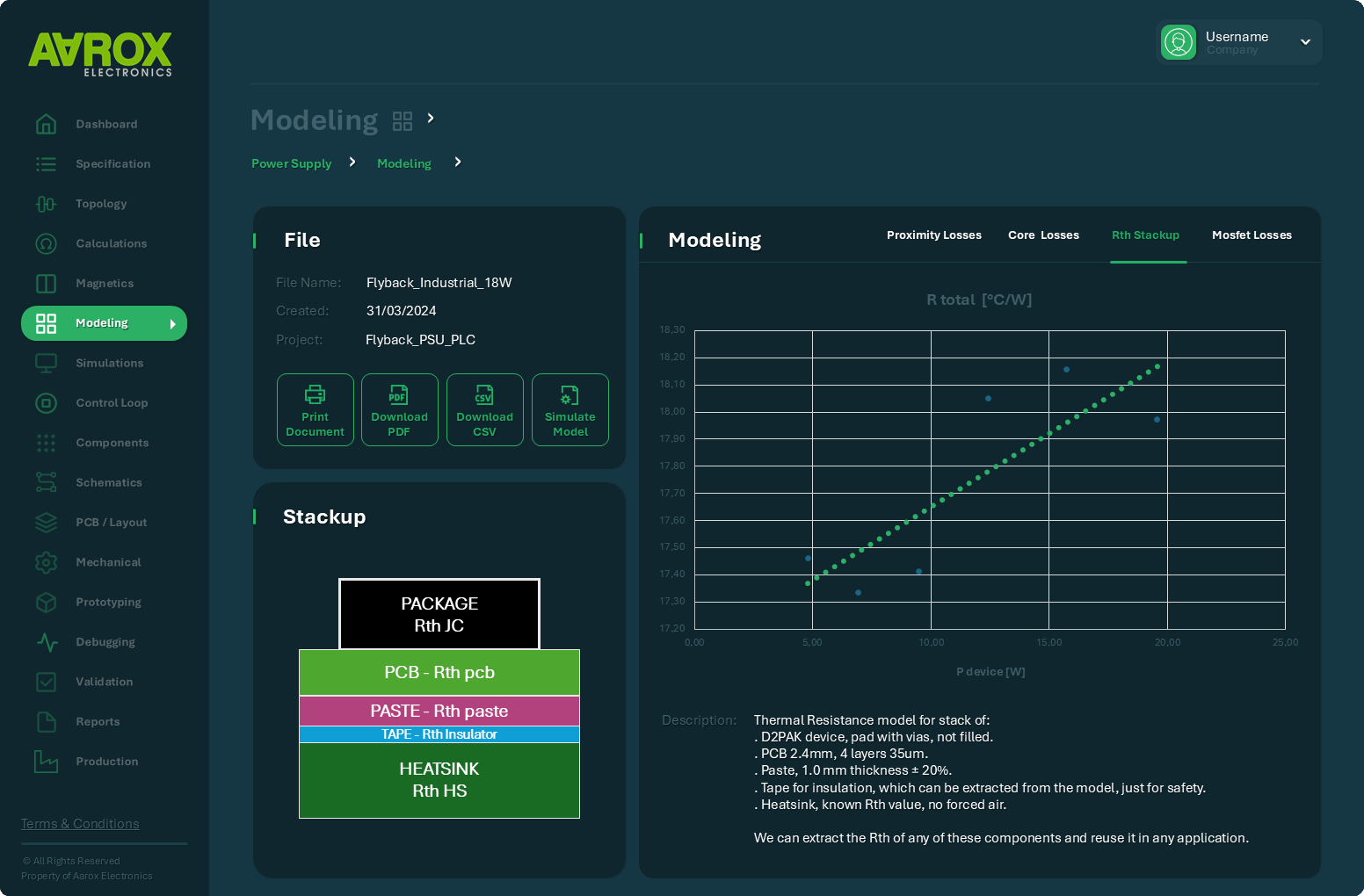

- 3. Modelling

We have behavioural models for many components, developed over the years. With these, we can accelerate the development TIME, achieving full working samples in record time.

- 4. Simulations

In complex projects or areas, we get supported by simulation SW, to predict behaviour or understand conditions that we cannot reproduced effectively on the LAB.

- 5. Control

We understand analog and digital control, being participated even in IC developments in the past. We have in our TOOLBOX, controllers, circuits and libraries for the digital DSPs.

With many power components in our toolbox

Many power devices, analysed, tested and benchmarked in many projects, some of them for very high volumes, where cost and reliability are the key for a competitive product.

- Si & SiC Mosfets

- Mosfets for ZVS

- Non-isolated Drivers

- Isolated Drivers

- Magnetics up to KW range

- Cost-effective CMCs

- PFC Chokes

- Flyback Transformers

- LLC + Lr Transformers

- Bidirectional Transformers

- PSFB Transformers

- Resonant Chokes

- Cost-effective Cores

- EMC Countermeasures

- Flyback Controllers

- PFC Controllers

- PFC + LLC Controllers

- LLC Controllers

- PSFB Controllers

- Multiphase Controllers

- Buck / Boost / Sepic ICs

- OR-ing & SYNC Rectification

- Current Sensors

- Op-Amp Circuits

- Short-circuit protections

- TI C2000 DSPs & Libraries

- Thermal interfaces

- Water cooling techniques

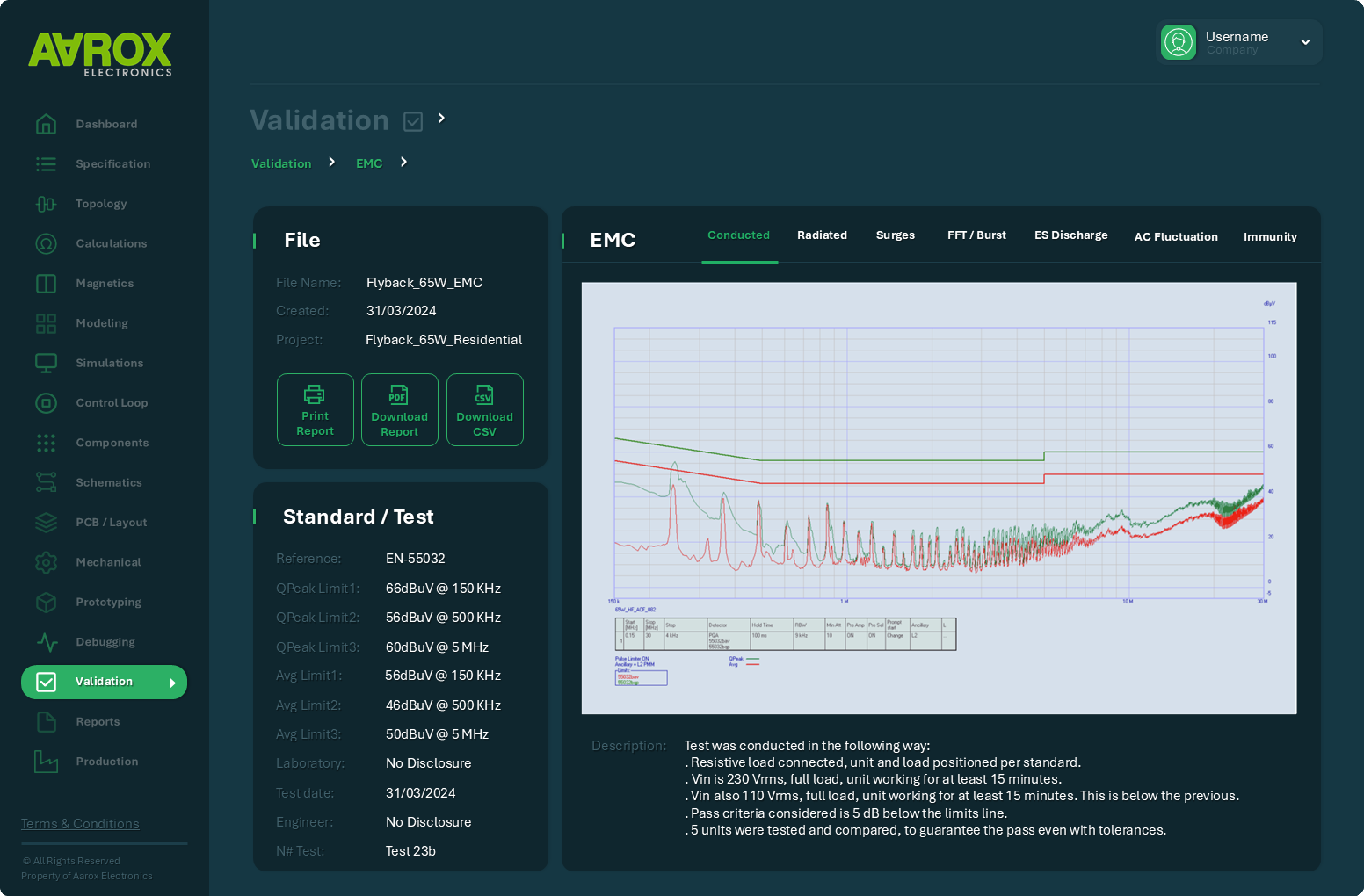

VALIDATION and EMC

With experience introducing products in high volume markets, up to several million, where the validation process and EMC must be taken to the extreme, to ensure top quality over the expected lifetime.